In the News

April 2025

Nathan Ewell gave a talk titled “Development of Degradable Electrospun Polycaprolactone Filter Media for Filtering Facepiece Respirators” at Materials Research Society (MRS) conference in Seattle.

March 2025

Natalie Mamrol gave a talk titled “Screening of Bio-Based Furanoate Polyesters for Sustainable Fibers” at American Chemical Society Spring 2025 Meeting and Expo; San Diego

March 2025

Natalie Mamrol presented a poster titled “Impact of Additives and Dyes on the Biodegradability of Textile Materials” at American Chemical Society Spring 2025 Meeting and Expo; San Diego

October 2024

Chinmay Gangal gave a talk titled “Modeling LLDPE resins in multilayer film heat-sealing with slip-link model” at AIChE 2024 annual conference in San Diego.

July 2024

Prof. Rutledge gave an invited talk titled “Nanofiber Technology for Personal Protection Equipment (PPE)” at the PolyU Distinguished Lecture, Hong Kong Polytechnic University, Research Centre of Textiles for Future Fashion, Hong Kong.

June 2024

Prof. Rutledge gave an invited talk titled “Electrospun Filtration Media for Personal Protection Equipment (PPE)” at the 8th International on Electrospinning (Electrospinning 2024), AGH University of Krakow, Krakow, Poland (invited lecturer).

May 2024

Prof. Rutledge gave an invited talk titled “Multiscale modeling of flow-induced crystallization in polymers” at the Department of Chemical Engineering, Princeton University, Princeton, NJ.

April 2024

Prof. Rutledge gave an invited talk titled “Engineering the crystallization and semicrystalline state of polymers through molecular modeling” at the Department of Macromolecular Science and Engineering, Case Western Reserve University.

March 2024

Dr. Marat Andreev gave an invited talk titled “Multiscale modeling of flow-induced crystallization in polymers” at the 19th International Conference on Deformation, Yield and Fracture of Polymers (DYFP24), Rolduc Abbey, Kerkrade, NL.

January 2024

Prof. Rutledge gave an invited talk titled “Nucleation of Polymer Crystals: Insights from Molecular Simulation” at the Department of Chemistry, Wellesley College.

December 2023

Congratulations to John Mikhail on defending his thesis titled “Understanding the Mechanisms of Shock-Induced Deformation in Polymeric Systems”.

November 2023

Congratulations to Nathan Volchko on defending his thesis titled “Understanding Heterogeneous Nucleation Mechanisms in Polyolefins”.

June 2023

Congratulations to Nathan Ewell on being selected as a 2023-24 Chemical Engineering MathWorks Engineering Fellow.

May 2023

Congratulations to Natalie Mamrol on receiving NSF Graduate Research Fellowship Program 2023 Award in Materials Research – Polymers Field “High Throughput Screening of Polyesters for Sustainable Fiber and Textile Development”.

Apr. 2023

Congratulations to Emily Song on successful completion of her doctoral thesis defense “Fabrication of Electrospun Anti-fouling Membranes for Emulsified Oil-water Separation”.

Nov 2022

Congratulations to Prof. Rutledge on AIChE Braskem Award for Excellence in Materials Engineering and Science, for “Molecular engineering of soft matter focused on understanding relationships between processing, structure and properties of engineered polymers with applications to polymer crystallization and crystallinity, and electrospun nanofibers”

Oct 2022

Prof. Rutledge shares ideas on innovation in the textile Industry as a panelist on “Co Creating Innovation for the Textile Industry” at the annual meeting of the Sustainable Apparel Coalition in Singapore

Oct 2022

Prof. Rutledge shares some of the insight gained

from the MITandFIT Advanced Fabrics Workshop at the 2022 AFFOA Membership Summit, and how a cross-disciplinary community of students is being created in engineering and design for textiles.

Oct 2021

Prof Rutledge speaks on “Challenges and Opportunities for Materials in the Textile Industry”, at the symposium on the Role of Materials in Addressing Climate Change and Sustainability, Materials Day at MIT.

May 2022

Congratulations to Natalie Mamrol on her qualification exam, and

Nathan Ewell on the successful proposal!

May 2022

Rutledge lab receives J-WAFS grant for oil/water separation problem.

[Read More]

March 2022

MIT News: “Prof. Rutledge discusses a proposal to reduce the carbon footprint of the textile industry, in response to MIT’s Climate Grand Challenge“.

September 2021

MIT News: “Why the future of textiles is collaborative“.

September 2021

Rutledge group contributes to working paper entitled “Transforming the Medical PPE Ecosystem“.

March 2021

Rutledge lab is featured in the second episode of “Project Frontline: Building a Response“, a documentary about the government/industry/university response in Massachusetts to the COVID pandemic in spring of 2020. [Part II: 11:32-minute mark]

March 2021

Congratulations to Gwen Wilcox for winning the 2021 MIT Excellence Award for her outstanding contributions!

December 2020

Professor Akira Koyama, who stayed with the Rutledge group in 2018-2019, published an article based on work done at MIT.

October 8, 2020

The Journal of Rheology releases new paper from Marat Andreev, David A. Nicholson, Anthony Kotula, Jonathan D. Moore, Jaap den Doelder, and Gregory C. Rutledge: “Rheology of crystallizing LLDPE”, Journal of Rheology 64, 1379 (2020)

June 18, 2020

Polymer releases new paper from David A. Nicholson and Gregory C. Rutledge:

“Flow-induced inhomogeneity and enhanced nucleation in a long alkane melt”, (2020)

May 22, 2020

Kedi Hu receives the Fulbright Fellowship!

[Full Story]

May 19, 2020

News feature on Junli Hao’s work to helping fight Covid-19

[Full Story]

April 30, 2020

Rutledge group’s work on initial testing of KN95 respirators gets into the news

[Full Story]

February 2020

Rutledge group welcomes Rachel Passos, PhD. She is a visiting postdoc from University of São Paulo, Brazil and will stay for 1 year.

January 20, 2020

Greg gives an invited talk on workshop on Flow-Induced Crystallisation in Polymers in Leeds and Bradford, United Kingdom.

January 8, 2020

David Nicholson successfully defends his PhD thesis “Molecular simulation of nucleation from flowing polymer melts”. Congratulation Dr. Nicholson!

January 3, 2020

Journal of Rheology releases new paper from Marat Andreev and Gregory C. Rutledge: “A slip-link model for rheology of entangled polymer melts with crystallization”, Journal of Rheology 64, 213 (2020)

June 9, 2019

MIT News: Getting the oil out of water

Yi-Min Lin, Chen Song, and Gregory C. Rutledge

Membrane-based separation is an important technique for removing emulsified oil from water. However, the mechanisms of fouling are complex due to the deformability and potential for coalescence and break-up of the oil droplets. Lin et al report direct, three-dimensional (3D) visualization of oil droplets on electrospun fiber microfiltration membranes after a period of membrane-based separation of oil-in-water emulsions, using a dual-channel confocal laser scanning microscopy (CLSM) technique in which both the fibers and the oil (dodecane) were fluorescently labeled. The morphology of the dodecane as foulant was observed for two different types of fibers, and as a function of separation time (i.e. “4D” imaging), as the oil accumulated within and upon the membranes. This technique is a powerful tool for characterizing the mechanisms of fouling in membranes used for liquid emulsion separations.

Rutledge Group and Course X students join forces to create innovative textiles – (July 17, 2019)

January 4, 2018

Rutledge lab’s new ultrafine fibers have exceptional strength

November 2018

NSF DMREF Project: A New Approach to Design of Polymer Morphology

Nathan W. Volchko, Corinne L. Carpenter, Alexander J. Bourque, Richard D. Braatz, and Gregory C. Rutledge

Advanced materials and their manufacture are essential to economic development, national security, and quality of life. MIT along with ExxonMobil is designing additives to produce lightweight polyolefins that are stiffer and tougher than those currently available and that benefit societal and economic requirements for energy and material conservation. This collaboration between academia and industry seeks to demonstrate a new paradigm for identifying essential relationships between molecular structure, morphology and performance, based on the close-knit and synergistic application of (i) molecular level simulation, (ii) experimental validation, (iii) materials design and optimization, and (iv) industrial applications.

Electrochemically Nanostructured Polymer Hybrids for Energy Storage

Wenda Tian, Xianwen Mao, Paul Brown, Gregory C. Rutledge, and T. Alan Hatton

(1st place at MIT Polymer Day poster competition in March, 2015)

Redox polymers (RPs) with non-conjugated backbones are rarely used for energy storage because of extremely low intrinsic conductivities. Conducting polymers (CPs) with conjugated backbones, though conductive, may suffer insufficient exposure to the electrolyte due to the often formed non-porous structure, thus hindering the ion doping/dedoping during the faradaic process. We overcome these limitations by creating a highly porous RP/CP hybrid via simultaneous electro-precipitation of a metallocene containing redox polymer, polyvinylferrocene (PVF), and electro-polymerization of a CP monomer, pyrrole. Due to the intermolecular interactions between pyrrole and the ferrocene moieties of PVF, the as-polymerized conducting polypyrrole becomes intertwined with the poorly conducting PVF, forming a highly porous polymer hybrid with significantly improved electrochemical performance.

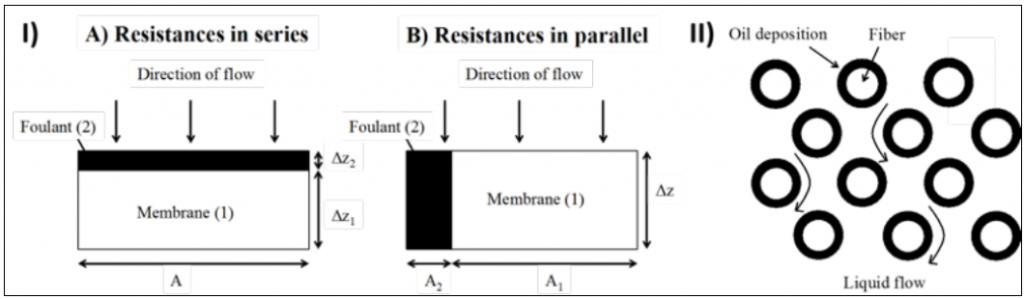

Electrospun Fiber Membranes for Oil/Water Separation

Simon Choong, Yi-Min Lin and Gregory C. Rutledge

The feasibility of using electrospun fiber membranes for microfiltration has been demonstrated on an oil-in-water emulsion. Electrospun fiber membranes were found to sustain fluxes 2-3 times higher than a commercial phase inversion membrane while removing a comparable amount of oil droplets. The fouling behavior of oil droplets on the membrane was modeled empirically, based on the resistance analysis in electrical circuit, and analytically, using a modified version of the permeability equation derived by Happel [1] for flow through fibrous media using the Navier-Stokes equation.

L.T. Choong, Y.M. Lin, G.C. Rutledge, “Separation of Oil-in-Water Emulsions Using Electrospun Fiber Membranes and Modeling of the Fouling Mechanism”, J. Membr. Sci. (submitted)

Electrospun Carbon Nanofiber Webs with Controlled Density of States for Sensor Applications

Xianwen Mao, Fritz Simeon, Gregory C. Rutledge and T. Alan Hatton

(1st place in the Student Paper competition at the Fiber Society meeting in Nov, 2012)

Electrospun carbon nanofiber webs with controlled density of states have been synthesized through varying carbonization conditions to manipulate the concentration of nanosized graphite domains. These materials exhibit adjustable electrochemical activity and biosensitivity: both electron transfer kinetics for various redox systems and direct electron transfer efficiencies with enzymes increase with the DOS of the CNF webs. (Advanced Materials, 2012)

Mechanical and Transport Properties of Layer-by-layer/Electrospun Nanofiber Composite Proton Exchange Membranes for Use in Direct Methanol Fuel Cells

Matthew Marchand Mannarino, David S. Liu, Paula T. Hammond, and Gregory C. Rutledge

(Oral presentation awarded 2nd place at 2012 MRS Membrane Symposium)

Improvements to the performance of thin solid polymer electrolytes for use as proton exchange membranes (PEMs) are critical for the advancement of the electrochemical energy devices such as direct methanol fuel cells (DMFCs). The essential properties for polyelectrolyte PEM used in DMFCs include: high ionic conductivity, low fuel/charge crossover, and mechanical stability. PEM fabrication by spray-assisted layer-by-layer (LbL) assembly of sulfonated poly(2,6-dimethyl-1,4-phenylene oxide) and poly(diallyl dimethyl ammonium chloride) [sPPO/PDAC] onto an electrospun fiber mat (EFM) scaffold has been shown to provide ionic conductivity comparable to that of the industry standard, Nafion®, while achieving a two order of magnitude reduction in methanol crossover. Electrospinning is used to create porous nanoscale polymer fiber scaffolds to provide mechanical support as well as mimic the percolated, fibrillar structure of water-swollen Nafion®. Poly(trimethyl hexamethylene terephthalamide) [PA 6(3)T], was used as the electrospun nanofiber “endo-skeleton” for the PEM due to its inherently high mechanical strength, tunable fiber diameter, high porosity, and relative ease of fabrication. Coating the PA 6(3)T EFMs by the vacuum-assisted spray-LbL technique produces composite membranes with conformally coated fibers throughout the bulk of the EFM and gives nanometer control of the thickness of the coating. Since the LbL process treats each fiber as an individual growth surface, entire EFMs (thickness ranging from 25 – 80 μm) can be filled up to 70%with less than 1 μm thick LbL coatings, while retaining up to 50% of the pristine LbL conductivity. In the absence of vacuum, the spray-LbL process forms a film covering all the pores of the EFM without penetrating into the fibers, thus creating a coherent methanol-impermeable capping layer. The mechanical properties of these composite LbL/EFM membranes are drastically improved over those of the LbL film alone, exhibiting the stiffness of PDAC/sPPO films when dry and the strength of the underlying EFM when hydrated. Improvements in the mechanical performance of the composite LbL/EFM PEMs are achieved by manipulating the structure of the underlying nanofiber matrix by heat treatment of the EFM post-spinning to increase the number of weld points between fibers and thus create a stronger fiber network. The dimensional stability of the composite PEMs under humidity cycling is superior to most conventional polyelectrolyte membranes, and the mechanical durability of the LbL/EFM PEMs was also found to be comparable to Nafion®. The composite LbL/EFM PEMs have been tested in a DMFC and preliminary results show higher open circuit voltage compared to Nafion®, as the result of reduced methanol permeability and comparable membrane impedance. Further optimization of the membrane electrode assembly and PEM conditioning indicate the potential for improved fuel cell output.(Advanced Functional Materials, 2013)

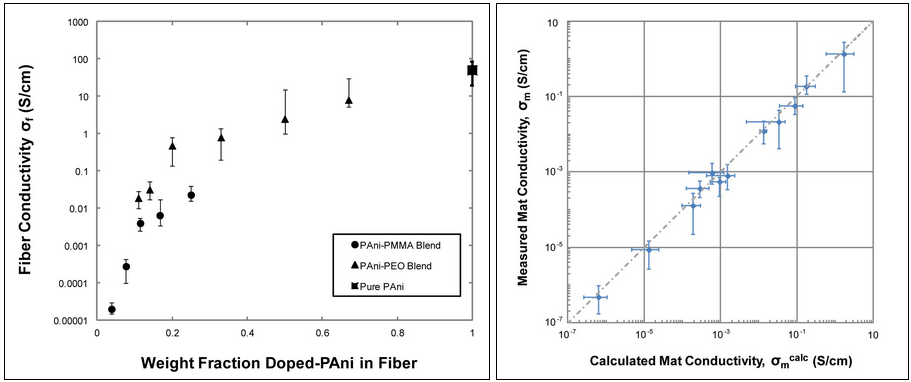

Electrical conductivity of electrospun polyaniline and polyaniline-blend fibers and mats

Yuxi Zhang and Gregory C. Rutledge

Submicrometer fibers of polyaniline (PAni) doped with (+)-camphor-10-sulfonic acid (HCSA) and blended with poly(methyl methacrylate) (PMMA) or poly(ethylene oxide) were electrospun over a range of compositions. Continuous, pure PAni fibers doped with HCSA were also produced by coaxial electrospinning and subsequent removal of the PMMA shell polymer. The electrical conductivities of both the fibers and the mats were characterized. The electrical conductivities of the fibers were found to increase exponentially with the weight percent of doped PAni in the fibers, with values as high as 50 ± 30 S/cm for as-electrospun fibers of 100% doped PAni and as high as 130 ± 40 S/cm upon further solid state drawing. These high electrical conductivities are attributed to the enhanced molecular orientation arising from extensional deformation in the electrospinning process and afterward during solid state drawing. A model is proposed that permits the calculation of mat conductivity as a function of fiber conductivity, mat porosity, and fiber orientation distribution; the results agree quantitatively with the independently measured mat conductivities. (Macromolecules, 2012, v45, 4238-4246)

On the importance of fiber curvature to the elastic moduli of electrospun nonwoven fiber meshes

Chia-Ling Pai, Mary C. Boyce, and Gregory C. Rutledge

Adequate mechanical integrity of nonwoven fabrics is generally a prerequisite for their practical usage. Nonwoven fiber mats of poly(trimethyl hexamethylene terephthalamide) (PA 6(3)T) with average fiber diameters from 0.1 to 3.6 microns were electrospun from solutions in dimethylformamide and formic acid and their in-plane mechanical response characterized. Two quantitative microstructure-based models that relate the Young’s moduli of these fabrics to those of the fibers are considered, one assuming straight fibers and the other allowing for curved fibers. It is found that the model allowing for curved fibers provides a quantitative relationship between the Young’s moduli of the mats and those of the fibers themselves. The governing factors that affect the mechanical properties of nonwoven mats are the porosity of the mats, the intrinsic fiber modulus, and the average fiber diameter, curvature (or “curl”) and distance between fiber-to-fiber junctions. Especially for submicron diameter fibers, both the intrinsic fiber properties and fiber curvature make important contributions to the mechanical behavior of their nonwoven fabrics. (Polymer, 2011, v52, 6126-6133)

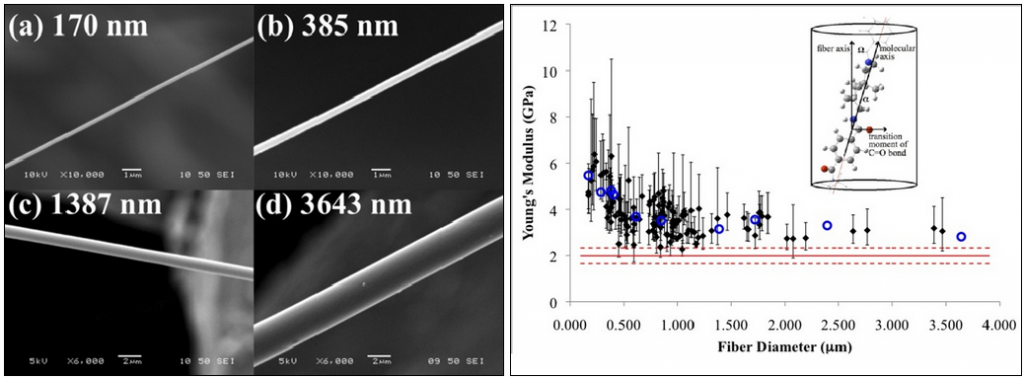

Mechanical properties of individual electrospun PA 6(3)T fibers and their variation with fiber diameter

Chia-Ling Pai, Mary C. Boyce, and Gregory C. Rutledge

Young’s modulus and yield strength of individual electrospun fibers of poly(trimethyl hexamethylene terephthalamide) (PA 6(3)T) have been obtained in uniaxial extension. The Young’s modulus is found to exhibit values in excess of the isotropic bulk value, and to increase with decreasing fiber diameter for fibers with diameter less than roughly 500 nm. The yield stress is also found to increase with decreasing fiber diameter. These trends are shown to correlate with increasing molecular level orientation within the fibers with decreasing fiber diameter. Using Ward’s aggregate model, the correlation between molecular orientation and fiber modulus can be explained, and reasonable determinations of the elastic constants of the molecular unit are obtained. (Polymer, 2011, v52, 2295-2301 )

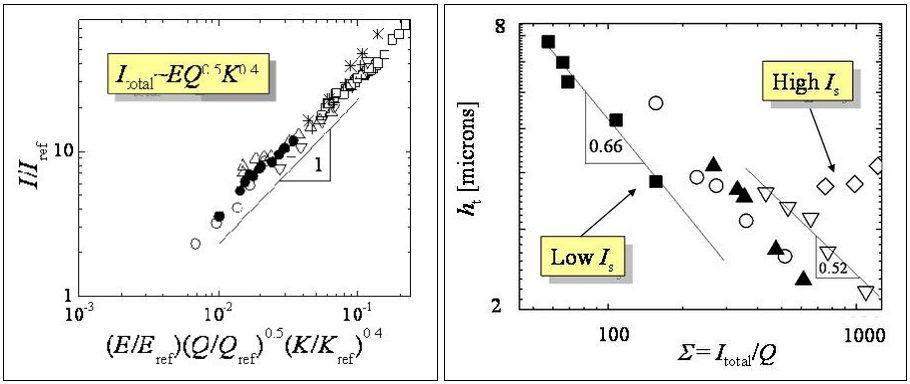

On the Measured Current in Electrospinning

P. K. Bhattacharjee, T. M. Schneider, M. P. Brenner, G. H. McKinley, and G. C. Rutledge

In determining the diameter of the fibers obtained in electrospinning, the current, I, carried by the electrified jet plays a fundamental role. When the surface tension force acting on the electrified jet balances the force due to surface charge repulsion, the diameter of the jet (ht) scales as ht ~ &Sigma 2/3 = (I/Q)2/3 where &Sigma is the volume charge density and Q is the flow rate of the fluid (Phys. Rev. Lett., 90, 144502, 2003). It is demonstrated that for linear homopolymers in organic solvents the total current (Itotal) measured in electrospinning follows a scaling law given by Itotal ~ EQ0.5K0.4, where K is the conductivity of the fluid and E is the electric field strength, calculated as a ratio of the imposed potential difference (V) and the distance between the electrodes (dg). It is further demonstrated that a part of the total current may consist of contributions from charged secondary jets that emanate from the surface of the primary jet and discharge at the counter electrode along with the primary jet. In such cases, the measured total current can be written as Itotal = I + Is, where the term Is signifies the contribution from the charged secondary jets. The secondary jetting phenomenon is invoked when the jet bends and the local electric field on the surface of the jet is intensified. Since the magnitude of I cannot be exactly determined in the presence of secondary jetting, &Sigma is typically estimated on the basis of the measured current, Itotal. It follows that, for cases where Is is small, ht ~ &Sigma2/3 = (I/Q)2/3. However for large values of Is the apparent scaling between ht and &Sigma can significantly deviate from theoretical predictions. These results provide valuable insight into the mechanisms that affect fiber formation in electrospinning and provide one explanation for the deviations from theoretical scaling behavior observed in practice. (J. Appl. Phys. 2010, 107, 044306)

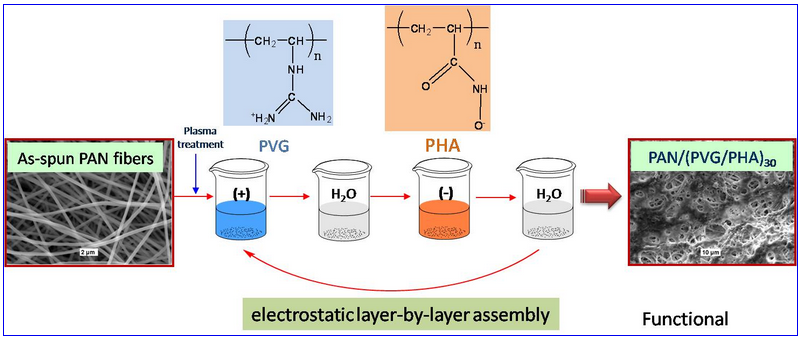

Multifunctional Electrospun Fabrics via Layer-by-Layer Electrostatic Assembly for Chemical and Biological Protection

Liang Chen, Lev Bromberg, Jung Ah Lee, Huan Zhang, Heidi Schreuder-Gibson, Phillip Gibson, John Walker, Paula T. Hammond, T. Alan Hatton and Gregory C. Rutledge

Breathable, chemical and biological detoxifying protective fabrics are obtained via functionalization of electrospun fiber mats using a layer-by-layer electrostatic assembly technique. Chemically reactive polyanion, poly(N-hydroxyacrylamide) or poly(hydroxamic acid) (PHA), and bactericidal polycation, poly (N-vinylguanidine) (PVG), were synthesized and electrostatically assembled to generate multifunctional coatings on prefabricated polyacrylonitrile (PAN) fiber mats. Reactivity of PHA in the hydrolysis of diisopropyl fluorophosphate (DFP), a close analog of the chemical warfare agent sarin, was demonstrated. The DFP degradation rate with PHA is comparable to that with compounds such as isonicotinhydroxamic acid methiodide, an efficient catalyst of organophosphate ester hydrolysis. Protective fabrics functionalized with PVG/PHA layers are able to degrade DFP mists, with DFP hydrolysis rates 60-fold higher than those with unmodified fabrics under identical conditions. Fabrics modified with PVG/PHA layers are bactericidal against E. coli and S. epidermidis. Breathability and barrier performance of functionalized fiber mats as protective fabrics were evaluated versus standard reference fabrics (Chemistry of Materials 2010, 22(4), 1429-1436).

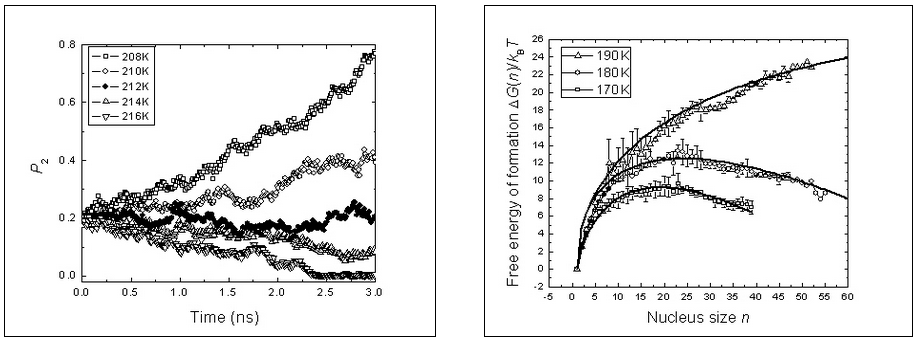

Molecular simulation of crystal nucleation in n-octane melts

Peng Yi, Gregory C. Rutledge

Homogeneous nucleation of the crystal phase in n-octane melts was studied by molecular simulation with a realistic, united-atom model for n-octane. The structure of the crystal phase and the melting point of n-octane were determined through molecular dynamics simulation and found to agree with experimental results. Molecular dynamics simulations were performed to observe the nucleation events at constant pressure and constant temperature corresponding to about 20% supercooling. Umbrella sampling Monte Carlo simulations were used to calculate the nucleation free energy for three temperatures, ranging from 8% to 20% supercooling, and to reveal details of the critical nucleus for the first time. The cylindrical nucleus model was found to provide a better quantitative description of the critical nucleus than the spherical nucleus model. The interfacial free energies of the cylinder model were calculated from the simulation data. As the temperature increased, the interfacial free energy of the side surface remained relatively unchanged, at 7 to 8 mJ/m2, whereas the interfacial free energy of the end surface decreased significantly from 5.4 mJ/m2 to about 3 mJ/m2. These results, and the methods employed, provide valuable and quantitative information regarding the rate limiting step during the solidification of chain molecules, with ramifications for both short alkanes and polymers (J. Chem. Phys., 2009, 131, 134902).

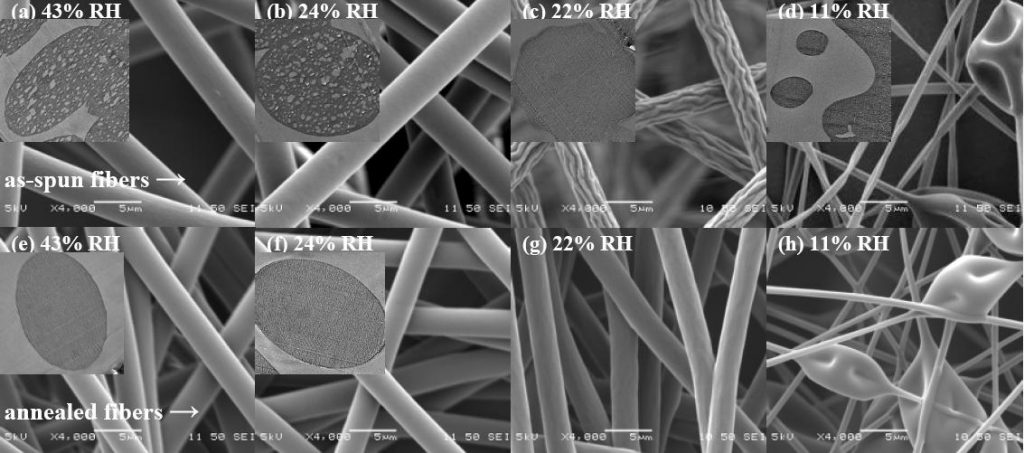

Morphology of Porous and Wrinkled Fibers of Polystyrene Electrospun from Dimethylformamide

Chia-Ling Pai *, Mary C. Boyce, and Gregory C. Rutledge

(* Finalist, 2009 AkzoNobel Student Award in Applied Polymer Science, Division of Polymer Materials Science and Engineering (PMSE), American Chemical Society)

Submicron diameter fibers of polystyrene (PS) are electrospun from solutions in dimethylformamide (DMF). It is found that the smooth fibers with highly porous interior formed in a humid environment, and wrinkled fibers with consolidated structures formed in a low humidity environment. The resulting interior and exterior structures are found to depend on a competition among the phase separation, solvent drying, and the buckling instability, which have important consequences for the properties of the fibers (Macromolecules, 2009, 42 (6), pp 21022114).

American Chemical Society 2007 National Meeting Presentation (August 2007)

Structure and Properties of Polyethylene Nanofibers from Molecular Dynamics Simulations (Macromolecules 2007, 40, 8483-8489)

Sezen Curgul, and Gregory C. Rutledge