Electrospun Fibers

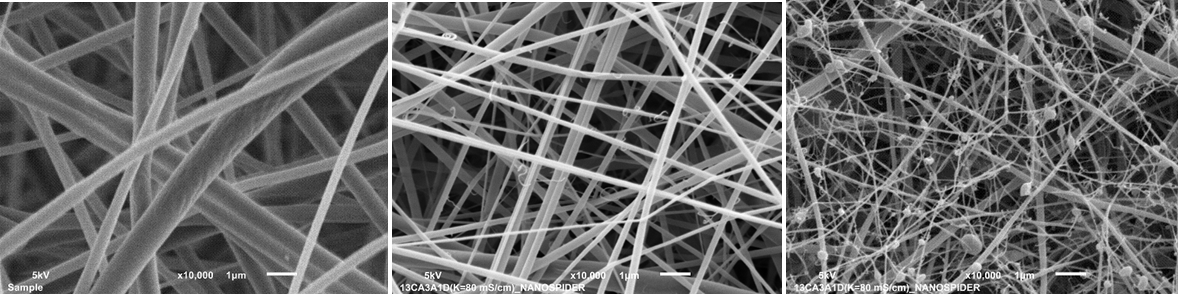

We use electrospinning to produce continuous fibers with sub-micrometer diameters. Fiber characteristics such as diameter, morphology and packing density are manipulated using operating parameters of the electrospinning technique and fiber processing. Our group has developed substantial expertise in the experimental realization of, as well as modeling and understanding the underlying mechanisms for, the production of fibers with different morphologies including beads-on-string, ribbons, wrinkled, and core-shell. Current works focus on developing electrospun membranes for applications such as air filtration, oil-water separation, and protective body armors.

Air filtration

Personnel: Junli Hao, Rachel Passos

Filtration of aerosol particles with sizes in the range of 0.1-0.5 μm is being studied using electrospun fibrous membranes. We are currently exploring the utility of such membranes to retain aerosol particles, with minimum air flow resistance, across a wide range of controlled particle sizes, face velocities and relative humidities. These observations are being studied for the purpose of developing advanced filtration materials with exceptional properties in retention of nanometer-sized aerosol particles and selectivity with respect to particle size and composition.

Oil-water separation

Personnel: Chen Song (Emily), Kedi Hu

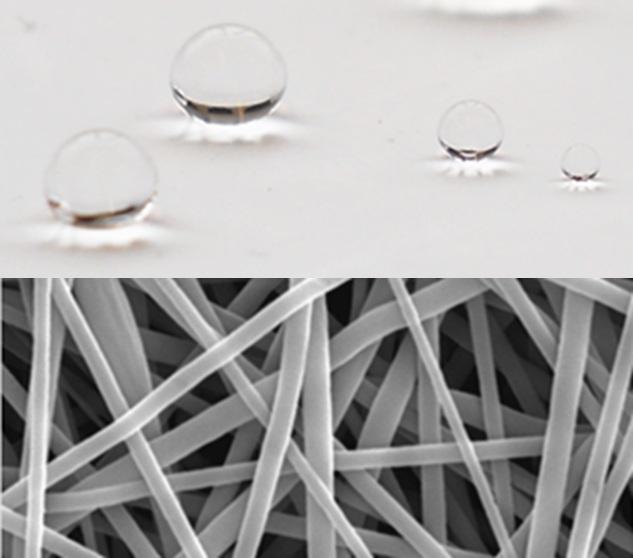

Membrane technologies have been widely applied in the field of wastewater treatment because of their high flux, good rejection, compact design and low energy cost. However, there are still challenges needed to be solved, such as fouling and poor membrane stability, to further widespread the application of this technology. This research project aims to develop advanced membranes for water treatment with better permeability, improved fouling resistance, and excellent mechanical strength using novel fabrication methods such as electrospinning that are scalable to large areas. The coupling between membrane structure, mechanical properties like membrane compressibility and hydraulic permeability is being analyzed. The relationships between system design, operating conditions, membrane properties, and fouling processes on the membranes are also being examined.

Liquid body armor

Personnel: Junli Hao

Liquid body armors that incorporate shear-thickening fluids (STFs) into fabrics have been gaining attention in recent years due to their improved flexibility and impact-resistance. However, some concerns of such liquid-solid composites include overtime decrease in liquid retention and shape stability. In this project, we use electrospun membranes instead of traditional fabrics as the matrix to hold the STFs in place, taking advantage of their capillary forces. The goal is to develop composite materials that are stable in shape, flexible in normal situation, and resistant upon impact.