Nanofiber Membranes

Personnel: Liang Chen, Jung Ah Lee, Ying Yang

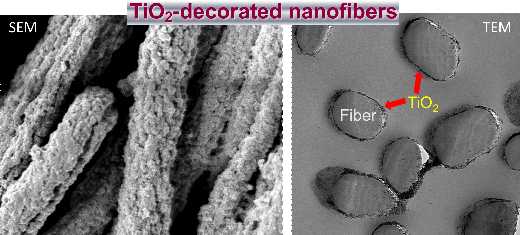

Electrospun fiber membranes possess high specific surface area, high porosity, small fiber size and low weight. Each of these remarkable properties suggest a broad range of applications. In our research, we take advantage of these properties to develop functional membranes through the inclusion of reactive or responsive compounds or nanoparticles upon and within the fibers. Such membranes have applications in chemical and biological protection, filtration and detoxification of toxic industrial gas or liquid streams, sensing and other areas. In one example, we have developed photocatalytically active nanofiber membranes combining both electrospinning and electrolyte nanoassembly techniques for protective clothing system, electrochemical power, sensor, and electrode applications. Highly reactive TiO2 nanoparticles were assembled on various electrospun polymeric nanofibers to achieve functional fiber membranes for photocatalytic degradation of toxic industrial chemicals.

We have also explored approaches to develop electrospun fiber-based chemical and/or biological protection clothing system or air filters. We fabricated reactive fiber mats with oxime functional groups in order to decompose toxic organophosophates, such as nerve agents like Sarin and Soman, and bactericidal electrospun fiber mats containing antibacterial agents such as chlorhexidine for biocidal protection. These functional fiber mats could be potentially incorporated into currently used system for the development of self-detoxifying protection garments or filters.

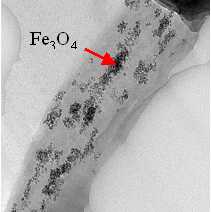

Another research interest involves the development of a new generation of stimuli-responsive membranes using electrospinning technology. These membranes can be functionalized to permit dynamic modulation of their properties using appropriate stimuli to enhance separation capabilities. We have focused on the fabrication of electrospun magnetic composite membranes with polymers such as PVA, PEO, PCL and PAN, which can be used in water treatment, and in chemical and biological processing.