Electrospun membranes for clean air

Personnel: Sangil Han, Saptarshi Chattopadhyay

Electrospinning polymeric solutions to prepare continuous fibers with sub-micrometer diameters, has recently received considerable attention in air filtration research due to its high surface area, high porosity, controlled fiber structure and interconnected pore structure, facilitating high gas absorption properties. Further, these materials have high efficiencies to remove sub-micrometer aerosol particles with relatively lower energy consumption (or pressure drop).

Our objectives in the field of electrospun membranes for clean air applications currently are two-fold: (a) the development of membranes whose gas permeability changes in response to a temperature change (i.e. thermo-responsive membranes), for application in the control of combustion and other high temperature processes; and (b) the design of filter materials using electrospun cellulose acetate and carbon fibers for application in aerosol filtration. Our thermo-responsive membranes are based on thermal transitions within one component or layer of a multi-component, multi-layer composite membrane. Such thermal transitions can lead to changes in morphology that alter the gas transport through the membrane. These membranes have potential as sensors as well as controllers and limiters on gas transport in high temperature processes. Besides temperature response, other triggers for a change of morphology can be envisioned.

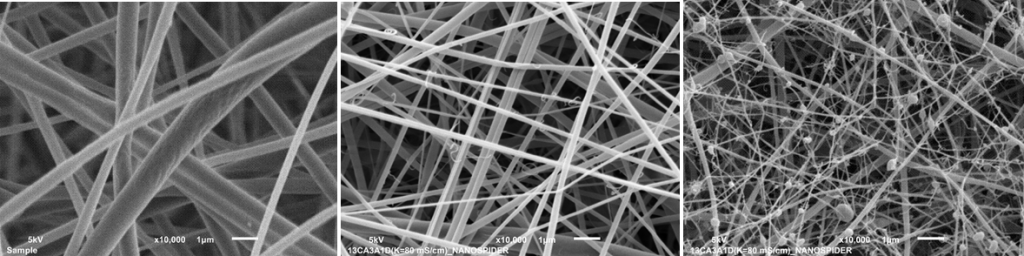

Filtration of aerosol particles with sizes in the range of 0.1-0.5 μm is being studied using electrospun fibrous membranes. Fiber characteristics such as diameter, morphology and packing density are manipulated using operating parameters of the electrospinning technique and fiber processing, as shown in the figure below. Our group has developed substantial expertise in the experimental realization of, as well as modeling and understanding the underlying mechanisms for, the production of fibers with such morphologies as beads-on-string, ribbons, wrinkled, and core-shell. We are currently exploring the utility of such membranes to retain aerosol particles, with minimum air flow resistance, across a wide range of controlled particle sizes, face velocities and relative humidities. These observations are being studied for the purpose of developing advanced filtration materials with exceptional properties in retention of nanometer-sized aerosol particles and selectivity with respect to particle size and composition.

For Further Information

- C.L. Pai, M.C. Boyce, G.C. Rutledge, “On the Morphology of Porous and Wrinkled Fibers of Polystyrene Electrospun from Dimethylformamide”, Macromolecules 2009, 42,(6), 2102-2114.

Abstract and full text, courtesy of American Chemical Society - L. Chen, L. Bromberg, J. A. Lee, H. Zhang, H. Schreuder-Gibson, P. Gibson, J. Walker, P.T. Hammond, T.A. Hatton, G.C. Rutledge, “Multifunctional Electrospun Fabrics via Layer-by-Layer Electrostatic Assembly for Chemical and Biological Protection”, Chemistry of Materials, 2010, 22 (4), 14291436.

Abstract and full text, courtesy of American Chemical Society - L. Chen, L. Bromberg, J. A. Lee, H. Zhang, H. Schreuder-Gibson, P. Gibson, J. Walker, P.T. Hammond, T.A. Hatton, G.C. Rutledge, “Multifunctional Electrospun Fabrics via Layer-by-Layer Electrostatic Assembly for Chemical and Biological Protection”, Chemistry of Materials, 2010, 22 (4), 14291436.

Abstract and full text, courtesy of American Chemical Society